The issue

Thames Water supplies water to several pressure-managed areas ( within the Central London area, including the Hammersmith PMA and the Putney East PMA. The two PMAs are densely populated and contain many tall buildings - 14,405 in the Hammersmith PMA and 16 360 in the Putney East PMA.

The Hammersmith PMA is segregated into 15 district metered

areas managed by electronically actuated pressure regulating valves. The

Putney East PMA is segregated into a total of 12 DMAs. Both PMAs contain relatively old

pipework and are highly susceptible to leakage. Current leakage losses are estimated to be 83ml/day

in the Hammersmith PMA and 10 5 ml /day in the Putney PMA. These significant losses correspond to the substantial, ongoing loss of revenue for Thames Water.

The purpose of the Thames Water PMA optimisation study was to investigate options that would change system operation to reduce leakage losses without adversely impacting customer service. Leakage from a water distribution network is a function of many factors, including pipe type, pipe age, quality of workmanship during pipe construction, and network operating pressure. Higher network pressures force more water out of openings in pipe joints and imperfections, resulting in higher leakage losses.

Key outcomes include:

• Minimisation of leakage losses

• Optimisation of system operations, including dynamic regulating valve settings

• 24 hours extended period simulation used in the analysis

The solution

Reducing operating pressures by modifying network controls (such as valve and pump settings) can reduce leakage losses. A trade-off in reducing operating pressures is that the supply pressure at consumer demand points is also reduced. Consequently, the optimisation challenge for the Thames PMAs was to find valve control strategies that could minimise leakage rates without violating minimum pressure requirements at supply points.

Optimizer™ WDS was linked to a hydraulic model with a 24 hour simulation time. Optimatics developed an add-in script that calculated leakage losses based on the hydraulic model results and field calibration data provided by Thames Water. These losses

were converted into an equivalent cost for optimisation. The optimisation

problem was formulated to include decisions regarding time-varying PRV settings at key

valve locations.

A non-typical approach was taken to assess the valve change’s impact

on the tall buildings, as many of the tall buildings in the PMAs had not been surveyed, and

it was unknown whether they already had private boosters installed. The approach

involved penalising nodes with pressures below tall building “target pressure” values with

a survey cost, plus an expectation booster pump installation cost.

The optimisation software carried out hydraulic analyses on solutions proposed by the optimisation algorithm to minimise a single objective function containing tall buildings costs, leakage reduction benefits, minimum pressure penalty cost, maximum velocity penalty costs, and penalty costs associated with changes to the distribution of supply from the various water sources.

The results

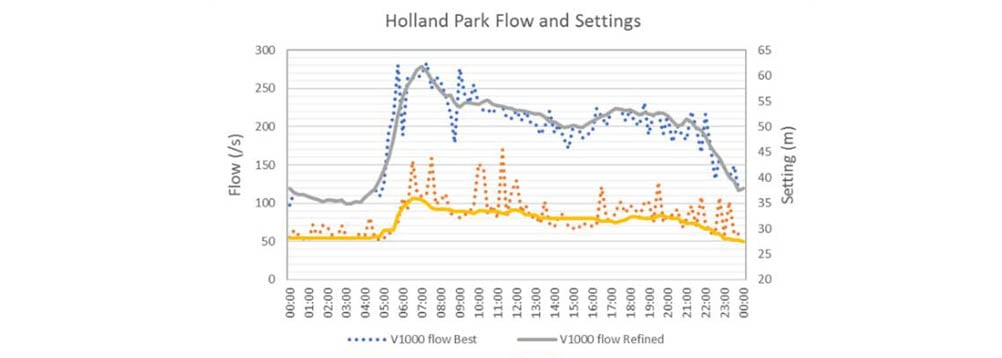

The initial optimization results produced excellent reductions in leakage losses; however, the optimal valve setting patterns found by Optimizer™ involved many oscillating setting changes, which may not have been practical to implement in the field. The patterns were subsequently smoothed out during post-processing, ultimately producing solutions that would generate a leakage benefit of more than £2 million whilst reducing the number of required booster pump stations.

Case Study Thames