Phosphorus recovery from wastewater

Today, phosphorus is mostly obtained from mined phosphate rock, highly limited in resources in Morocco, China and USA. Due to its geographical limitations, recovery and reuse of phosphorus is gaining the attention globally. 20% of current world demand of phosphorus could be covered by recovery from wastewater.

Without reuse of phosphorus, depletion is foreseen in 100 years from now and the European Commission has classified phosphorus among the 20 “critical materials”.

Without reuse of phosphorus, depletion is foreseen in 100 years from now and the European Commission has classified phosphorus among the 20 “critical materials”.

Technology that contributes to the circular economy and resource recycling

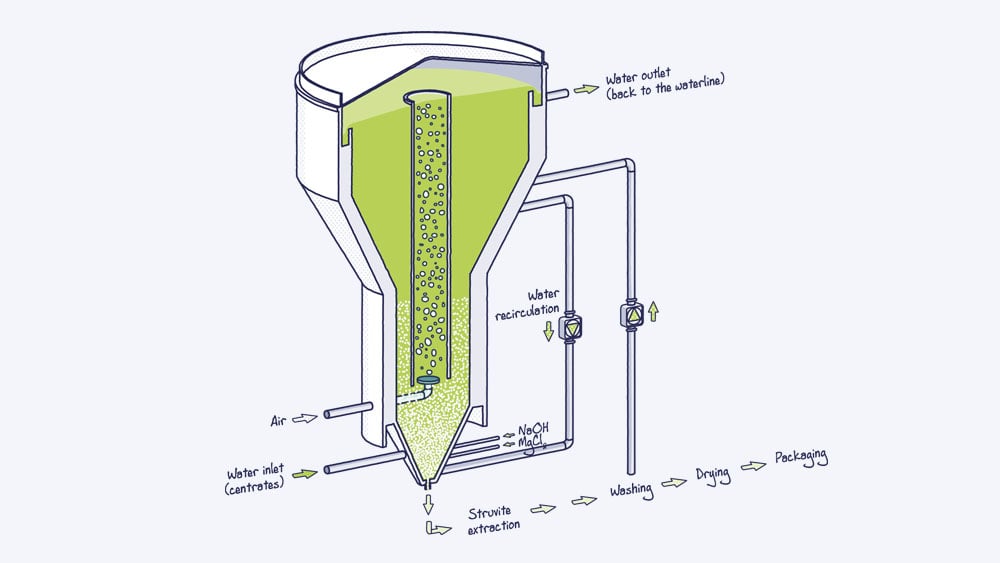

We developed a solution that extracts phosphorus via struvite from wastewater and turns it into a fertilizer.

The heart of Phosphogreen™ process consists injecting magnesium chloride to obtain precipitation-crystallization of struvite. Struvite is then extracted at the bottom of the reactor, washed, drained and dried before packaging.

Image Generic - Phosphogreen illustration

Image Generic - Phosphogreen illustration

Mass balance with up to 50% phosphorus recovery

Our technology recovers phosphorus from a side stream in wastewater treatment plant and operates on two streams of phosphorus reject water. This configuration allows to recover 40-50% of the phosphorus from incoming water.

Phosphogreen™ solution was fist implemented in a full-scale at Marselisborg wastewater treatment plant located in Aarhus.

The main reason was to solve an existing problem with struvite scaling in old and new pipes and present sand in digesters. Implementation of phosphorus recovery would eliminate those issues meanwhile increasing a green image of the client’s wastewater plant and its contribution to circular economy.

Phosphogreen™ solution was fist implemented in a full-scale at Marselisborg wastewater treatment plant located in Aarhus.

The main reason was to solve an existing problem with struvite scaling in old and new pipes and present sand in digesters. Implementation of phosphorus recovery would eliminate those issues meanwhile increasing a green image of the client’s wastewater plant and its contribution to circular economy.

Total struvite production ranges between 650-800kg per day that can be sold on the market as agricultural fertilizers containing:

- 12,5% phosphorus

- 5,5% nitrogen

- 10% magnesium

with granules sizes between 1 to 3 mm.

Contact our expert

Per Kroyer Christensen

CEO of SUEZ Denmark

[email protected]

SUEZ in Danemark

SUEZ in Danemark