Deconstruct a building with the ambitious target of reaching a waste recovery and reuse rate in excess of 70%

In 2015, SUEZ launched the NExtMat project in the Open Lab Ideas Laboratory®, with the aim of developing new materials recovery solutions that turn waste into resources. The project was perfectly in line with the French law on the energy transition and green growth, passed on 17 August 2015, with a view to recovering 70% of construction and demolition waste as materials by 2020. Waste management has become a major issue for public and private organisations tasked with large-scale development and civil works projects.

The Bouygues Group, which faces the problem of building waste in its construction activities (assembly, real estate, renovation, construction), teamed up with SUEZ to examine the keys to the successful reorganisation of the sector.

SUEZ and Bouygues Rénovation Privée joined forces in an experimental project to renovate a site measuring about 4,800 m2 in the heart of Neuilly in Greater Paris, by selectively deconstructing a building in a confined space with only one skip available on the work site.

The challenge consisted of setting up an operational organisation to separate the waste produced on-site in order to achieve a material recovery rate in excess of 70%, while also meeting the regulations that will come into force in 2020.

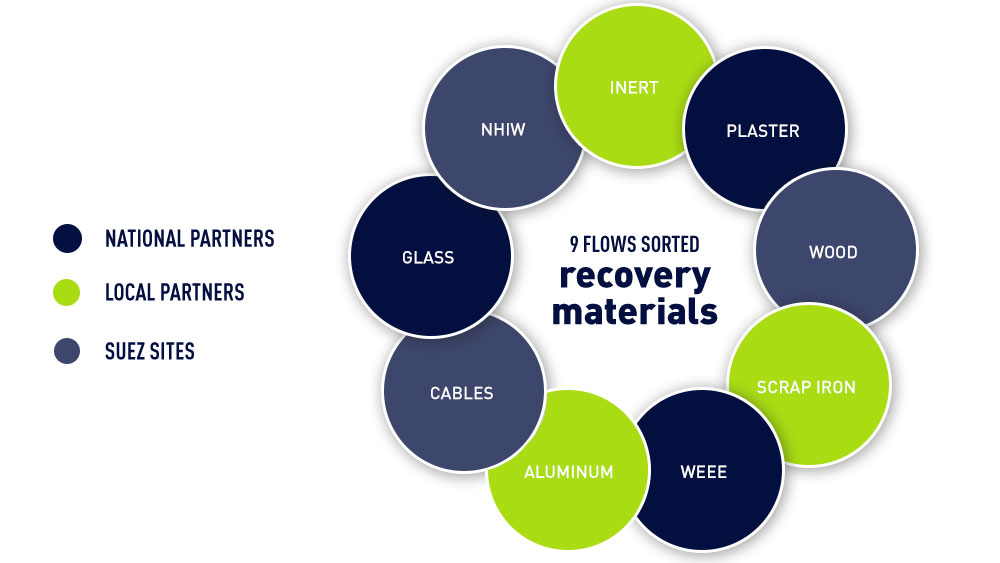

An original solution to sort nine material flows at source and to identify and organise the recovery channels nationwide

Monitoring of the sorting process and traceability of the flows

The SUEZ teams opted for the selective sorting of the materials on-site as and when they were dismantled, in order to optimise the sorting and evacuation of the waste in this very confined space.

Selective deconstruction and the control of the sorting of products and waste demand close oversight of the operations (waste processing sites, secure storage, traceability, sales corners or donations, etc.).

The different types of materials (cables, rubble, glazing, etc.) were sorted and grouped together on each floor under the watchful eye of a person, known as the “green man”, a technician ensuring that the on-site sorting operations ran smoothly.

Each type of material was then picked up in turn and taken to a mass groupage and logistics platform on SUEZ’s site in Gennevilliers.

Identification and organisation of the recovery channels

Organising a re-use and recovery channels for deconstruction materials involves switching from a "waste-based" to a "resource-based" vision and more collaborative ways of working together.

It was necessary to first analyse the economy of these “resource” products for the deconstruction site, but also on a regional scale, in order to guarantee that the ecosystem would make financial sense for all the players involved and for the recovery and re-use project.

74.6% of the materials were recycled and re-used by entering partnerships with the local recycling channels (Sibelco for glass and plasterboard), Group subsidiaries (NextMetal, which recycles used cables to produce 99.8% pure copper to make high-quality cables) and eco-organisations, such as Valdelia for the recovery of used office furniture, and Recylum for the recycling of lamps and professional electrical equipment.

A new made-to-measure waste management solution that puts the circular economy at the heart of work sites

The experimental project between Bouygues Construction et SUEZ provided an opportunity to conduct a life-sized test of the viability and the suitability of these new solutions in the design phase, before actual implementation. The solution highlighted SUEZ’s expertise in consultancy and support in the realm of the circular economy and regulatory compliance.

The project, which was finalised in 2017, was the first ever work site in France in a confined space that achieved such unprecedented levels of separation and recovery: 9 flows of materials sorted for re-use and recycling and the recovery of 74.6% of the building materials on the site.

Circular Economy Project Manager - Bouygues Bâtiment Ile-de-France

batiRIM®: a digital solution for the selective deconstruction of buildings

Thanks to this anticipatory approach and the digital modelling of material flows, SUEZ hopes to achieve safe, compliant selective deconstruction.

batiRIM®, the first digital solution for the selective deconstruction of buildings – SUEZ

Credit: SUEZ group