Overview

The

Prospect Water Filtration Plant is one of the world’s largest water

filtration plants, supplying reliable drinking water to 85% of Sydney’s

population.

Operated by our team in the Greater Western Sydney region, the Prospect Plant operates 24/7, has a design capacity to treat up to three billion litres of water per day, and uses innovative water filtration techniques to purify Sydney’s water.

Since its opening on the 4 November 1996, the plant has been providing consistently safe and reliable drinking water that complies with the National Health and Medical Research Council’s Guidelines for Australian Drinking Water.

Operated by our team in the Greater Western Sydney region, the Prospect Plant operates 24/7, has a design capacity to treat up to three billion litres of water per day, and uses innovative water filtration techniques to purify Sydney’s water.

Since its opening on the 4 November 1996, the plant has been providing consistently safe and reliable drinking water that complies with the National Health and Medical Research Council’s Guidelines for Australian Drinking Water.

Glass half full

In 1967, the growth of Sydney, coupled with drought, brought into sharp focus the need for a more secure water supply for residents in Sydney. To meet these demands, Australia’s largest water utility, providing water, wastewater, recycled water and selected stormwater services to the region, Sydney Water, has been evolving to supply drinking water for the rapidly growing population, as well as securing water resources for the future.

In response to the recurrent drought and to meet Sydney’s population growth demands, Sydney Water needed to secure the water supply for its community.

Our construction of the Prospect Water Filtration Plant in the 90s was a part of this evolution to meet the increasing demand for reliable water supply in Sydney. In 1993, we were awarded the contract to design, build, operate and maintain the plant for 25 years.

In response to the recurrent drought and to meet Sydney’s population growth demands, Sydney Water needed to secure the water supply for its community.

Our construction of the Prospect Water Filtration Plant in the 90s was a part of this evolution to meet the increasing demand for reliable water supply in Sydney. In 1993, we were awarded the contract to design, build, operate and maintain the plant for 25 years.

Operational reliability, every day

At SUEZ, we understand that operational reliability and continuity are critical when providing drinking water services to a large population. As such, ensuring the highest water quality through robust operation and maintenance practices has been our focus from the first day of the project.

We implemented an automated process management system to oversee the treatment process, as well as control the water quality. Moreover, our highly qualified teams undergo regular training to ensure they’re equipped with the necessary skills and knowhow on the latest systems.

Thanks to the system improvements and the ongoing development of our teams, the average treated water quality has been delivered consistently within Sydney’s Water’s contractual requirements since commissioning. With the compact and cost-effective design in place, our teams’ focus is ensuring the operational reliability and continuity of the plant.

We implemented an automated process management system to oversee the treatment process, as well as control the water quality. Moreover, our highly qualified teams undergo regular training to ensure they’re equipped with the necessary skills and knowhow on the latest systems.

Thanks to the system improvements and the ongoing development of our teams, the average treated water quality has been delivered consistently within Sydney’s Water’s contractual requirements since commissioning. With the compact and cost-effective design in place, our teams’ focus is ensuring the operational reliability and continuity of the plant.

An innovative design for efficient operation

The plant’s hydraulics were a challenge from the first day of the design stage. Its location and layout only allowed 5.2m of head for gravity flow through the plant. To solve the problem, we incorporated passive control systems in the plant, which enabled +/- 2% of accuracy in flow split to each filter.

Each of our four contact channels was over four metres wide and six metres deep. To ensure rapid and even dispersion and efficiency of this size, we developed leading-edge chemical mixing systems. We also conducted hydraulic flash mixing on a scale that has never been attempted before.

The plant is designed to enable solids to be removed directly on the filters without requiring a sedimentation stage. This resulted in 50% less backwash water used during the filtration process. Given the filtration rate of 24 m/h is double that of conventional filters, this saves an incredible amount of water during the filtration process.

Each of our four contact channels was over four metres wide and six metres deep. To ensure rapid and even dispersion and efficiency of this size, we developed leading-edge chemical mixing systems. We also conducted hydraulic flash mixing on a scale that has never been attempted before.

The plant is designed to enable solids to be removed directly on the filters without requiring a sedimentation stage. This resulted in 50% less backwash water used during the filtration process. Given the filtration rate of 24 m/h is double that of conventional filters, this saves an incredible amount of water during the filtration process.

Water for all

As a result, the plant has been operating at its optimum, providing reliable drinking water to 85% of Sydneysiders.

To overcome the myriad of site limitations, as well as meet Sydney Water’s population growth needs, we delivered a compact and cost-effective solution, saving our client approximately $40 million during the design and build stages.

Our teams worked hard to provide a reliable design and construction. As a result, we successfully completed the 30-day operating trial during commissioning without a single failure, which Sydney Water described as ‘exemplary’.

Through our collaborative partnership with Sydney Water and continuous improvement of the plant’s operational efficiency and reliability, the Prospect Water Filtration Plant continues to deliver top-quality drinking water for Sydney – now and into the future.

To overcome the myriad of site limitations, as well as meet Sydney Water’s population growth needs, we delivered a compact and cost-effective solution, saving our client approximately $40 million during the design and build stages.

Our teams worked hard to provide a reliable design and construction. As a result, we successfully completed the 30-day operating trial during commissioning without a single failure, which Sydney Water described as ‘exemplary’.

Through our collaborative partnership with Sydney Water and continuous improvement of the plant’s operational efficiency and reliability, the Prospect Water Filtration Plant continues to deliver top-quality drinking water for Sydney – now and into the future.

3,000

MLD

water treatment capacity

4

million

population served

> 25

years

of partnership

For more information download our Prospect Water Filtration Plant

3MB

PDF

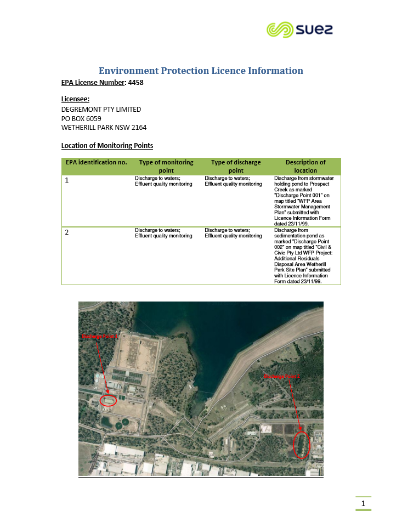

EPA Licence Information

254KB

PDF

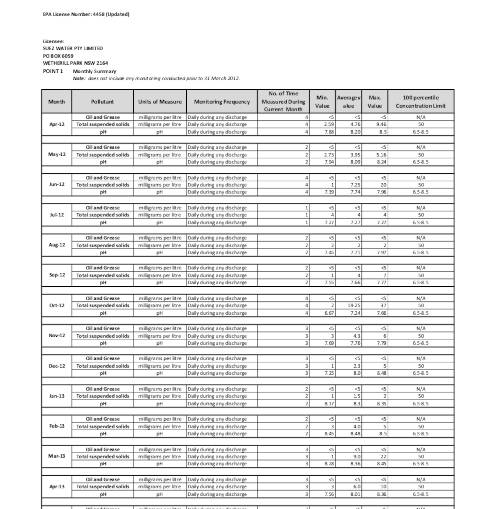

PWFP Storm Water Monitoring Results updated June 27th, 2025

681KB

PDF

Pollution Incident Response Management Plan - Notification

224KB

PDF

Pollution Incident Response Management Plan - PIRMP

592KB

PDF